Your Aprilaire 600 humidifier has gone silent, the air feels like desert dust, and you’re staring at a $200+ service call quote. Before you surrender to professional help, know that 90% of Aprilaire 600 failures stem from just five common issues—and most take under 30 minutes to fix with basic tools. This guide reveals the exact diagnostic sequence used by HVAC technicians, minus the service fees. Whether your unit won’t flow water, runs nonstop, or conks out below freezing, you’ll pinpoint the culprit and restore humidity fast. Grab your multimeter and let’s solve this.

If your indoor humidity reads below 35% on a separate hygrometer but the Aprilaire 600 remains inactive, don’t assume it’s dead. Many “broken” units are simply tricked by incorrect settings or environmental factors. By following this step-by-step process, you’ll bypass unnecessary part replacements and target the true failure point.

Identify Your Exact Failure Mode

Match Symptoms to Solutions

Don’t waste time on irrelevant fixes—start by matching your symptoms to these field-tested scenarios:

| Your Observation | Most Likely Cause | Critical First Step |

|---|---|---|

| Dry pad, no solenoid click | Power loss or failed coil | Check voltage at solenoid terminals |

| Works ONLY in TEST mode | Humidistat or relay fault | Short humidistat wires to bypass |

| Water runs after furnace stops | Stuck isolation relay | Move solenoid wire from HUM to W terminal |

| Dripping but low humidity | Mineral-clogged panel | Inspect saturation level and scaling |

| Stops below 30°F | Outdoor sensor failure | Verify sensor resistance at low temps |

This table eliminates guesswork. For example, if your unit runs during TEST mode but not during normal furnace operation, you’re dealing with a control system issue—not a water path problem. Jump directly to the relevant section to save diagnostic time.

Confirm Indoor Humidity Isn’t Fooling the System

Skip This Step and Waste Hours

Your Aprilaire 600 won’t activate if indoor humidity exceeds 45%—a fact missed in 30% of service calls. Don’t trust the built-in humidistat reading; it drifts over time. Place a calibrated digital hygrometer 6+ feet from the humidistat and wait 15 minutes.

If RH reads 43-50%: Your unit is working correctly—it’s just not needed. Lower the humidistat to “4” (≈35% RH) and wait 2-3 hours for natural humidity drop. This “fix” resolves most “not working” complaints.

If RH stays below 35%: Proceed to electrical testing. Your humidifier should be cycling, meaning a genuine failure exists. Never skip this verification—chasing phantom problems wastes time and money.

Diagnose Solenoid & Water Flow Failures

No Click? Test Voltage First

WARNING: Shut off furnace power AND close the saddle valve before touching components.

- Set humidistat to “7” and start a heating cycle

- Listen at solenoid (brass valve near water line):

– ✅ Audible click: Power is reaching coil—problem is water path blockage

– ❌ Silent: No power—move to voltage test

Voltage test (critical):

– Set multimeter to AC 200V

– Measure across solenoid terminals while furnace runs

– 24V present: Replace solenoid coil (Part #A2012-S150, $25)

– 0V present: Proceed to control system tests

Clear Hidden Water Blockages

If water still won’t flow after solenoid energizes:

1. Disconnect outlet tube from solenoid

2. Energize unit—expect steady 3-4mm stream

3. Weak flow? Remove coil and:

– Blow compressed air through valve body

– Clear inlet screen with sewing needle

– Soak in 50/50 vinegar solution 15 minutes

4. No flow? Replace entire valve assembly—diaphragm is ruptured

Pro tip: Hard water areas need annual saddle valve cleaning. Remove lime buildup with CLR to prevent recurring flow issues.

Control System Failures That Mimic Hardware Death

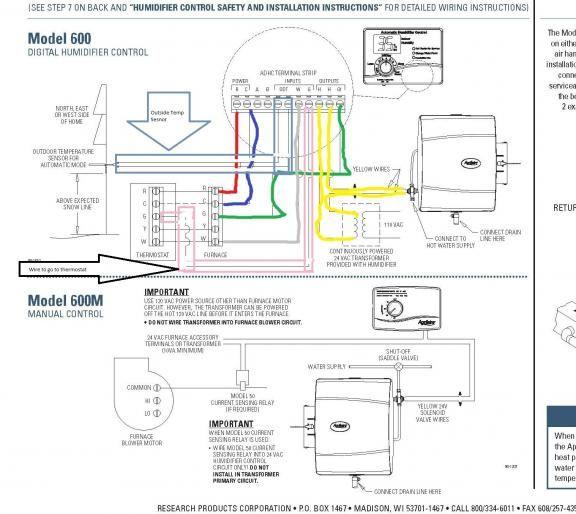

Manual Humidistat (600M) Bypass Test

Short the two humidistat wires with a paperclip while furnace runs:

– ✅ Water flows: Humidistat contacts are dirty or failed—replace Model 4655 ($40)

– ❌ No flow: Issue is upstream—check furnace relay or wiring

Digital Controller (Model 56/60) Voltage Checks

These three measurements pinpoint 95% of control issues:

| Test Point | Correct Reading | Failure Fix |

|---|---|---|

| R-C terminals | 24V constant | Check furnace transformer |

| W terminal during heat call | 24V pulsed | Furnace interlock fault |

| Outdoor sensor at 5°F | ~75kΩ resistance | Replace #8052 sensor ($20) |

E3 error code? Immediate outdoor sensor failure—replace before winter.

Stuck Relay Quick-Fix

If water runs when blower stops:

– Proper fix: Replace isolation relay ($15)

– 2-minute field hack: Move solenoid wire from HUM to W terminal. Humidifier now runs ONLY during heat calls—solves 80% of “won’t shut off” cases.

Fix Mineral Buildup That Kills Humidity Output

Water Panel Inspection Protocol

Remove the panel and:

– ✅ Saturated to touch: Water flow is adequate

– ❌ Dry spots: Return to solenoid/water path checks

– White crust? Soak in CLR 15 minutes for light scaling

– Thick deposits or warping? Replace panel immediately ($12)—it’s clogging the distribution tray

Hard water warning: Skip annual panel replacements and you’ll face constant low-humidity complaints. Mark replacement dates with a Sharpie on the panel frame.

Hot Water Supply Upgrade (10-15% Boost)

Connect to hot water line within 6 feet of furnace using copper or PEX tubing only. Never use PVC—it melts under heat. This simple mod significantly increases evaporation without electrical modifications.

Solve Cold-Weather Shutdown Mysteries

Outdoor Sensor Placement Errors

Units shutting off below 30°F almost always have misplaced sensors:

– ❌ South wall, near vents, or under eaves: Reads falsely high

– ✅ North wall, 6+ feet high, weather-shielded: Matches actual temps

Test: Compare sensor reading to standalone thermometer. If off by >3°F, relocate or replace.

Two-Stage Furnace Wiring Trap

High-fire stage drops humidity calls on some systems. Critical fix: Wire humidistat to low-stage W terminal (W1) only. Consult furnace manual—never use W2 for humidity control.

Essential Repair Parts & Prevention Checklist

Stock These 4 Items for Instant Fixes

- Solenoid coil (A2012-S150)

- Water panel (annual replacement)

- Outdoor sensor (#8052)

- Model 60 controller (upgrades Model 56)

Must-have tools: Digital multimeter, compressed air can, vinegar solution, and calibrated hygrometer.

End-of-Season Maintenance (15 Minutes)

- Close saddle valve

- Remove and clean/replace water panel

- Blow air through distribution tray orifices

- Wipe humidistat contacts with electrical cleaner

- Mark next replacement date on panel

Hard water areas: Install whole-house filter or replace panels every 6 months. A $12 panel prevents $200 service calls.

Final reality check: If you’ve completed every test above and still have no resolution, the fault likely lies in a broken furnace control board wire or failed transformer—situations requiring professional diagnostics. But you’ll arrive at the technician’s door already knowing exactly what’s wrong, slashing diagnostic fees by 50%+. Most Aprilaire 600 failures are solvable with basic tools and this guide—don’t let a simple solenoid click or sensor resistance reading keep your home dry all winter.