Dry indoor air can aggravate respiratory issues, damage wooden furniture, and create uncomfortable static—especially in winter. Many turn to ultrasonic humidifiers for quiet, energy-efficient relief, but when building, repairing, or upgrading, finding the right ultrasonic humidifier component is critical. With a maze of disc sizes, frequencies, and driver configurations, selecting incompatible or low-quality parts can lead to poor mist output, premature failure, or even safety risks.

We analyzed over 50 components—from 16mm ceramic discs to advanced USB modules—evaluating frequency, material durability, spray control, and real-world performance. Our picks balance mist efficiency, longevity, and ease of integration, whether you’re repairing a unit or designing a custom system. Key factors include disc frequency (1.70MHz for fine mist, 108kHz for power), titanium plating for corrosion resistance, and smart features like automatic shut-off.

Keep reading to discover the best ultrasonic humidifier components for every need and budget.

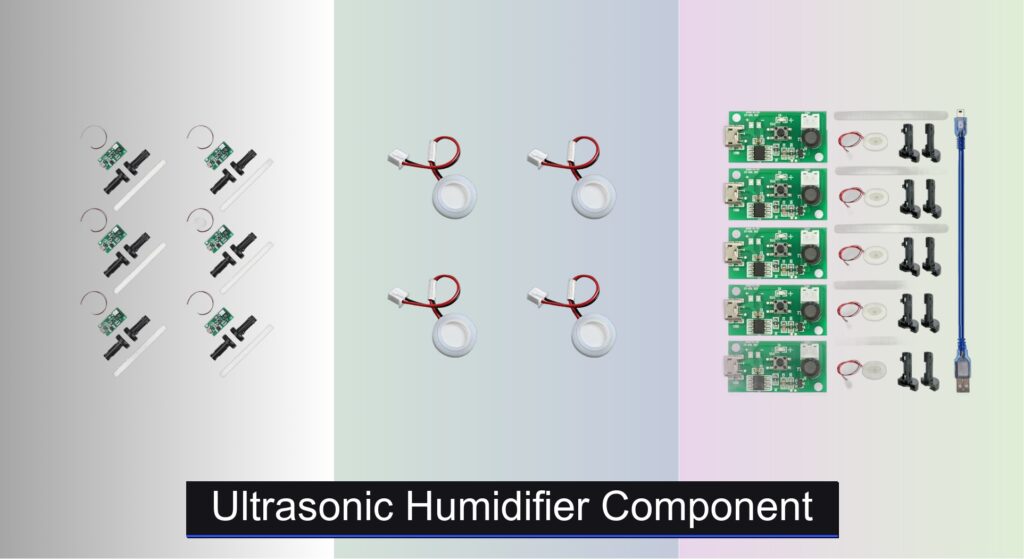

Best Options at a Glance

ITROLLE 4PCS 16mm Ultrasonic Discs with Wires

Best Value Replacement

- 16mm

- Ceramic with titanium plating

- 7cm

- 4 pcs

- 20mm

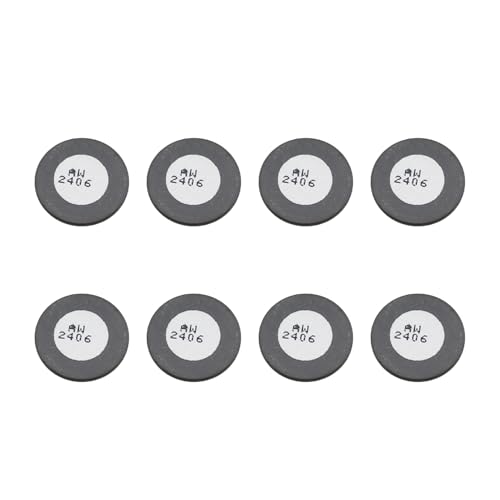

SQXBK 8PCS 16mm Ceramic Discs

Best Budget Pack

- 8 pcs

- Ceramic

- 16 mm

- Home, Pool, Aquarium

- Long

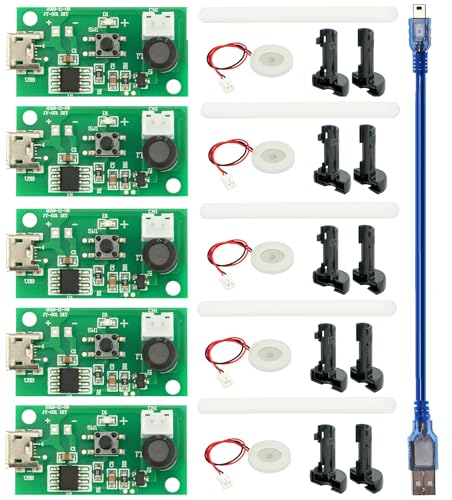

6Pcs USB Humidifier Module with LED

Best Overall

- 5V

- White side up, steel side down

- 5″um

- 7-color, 2 modes

- Continuous, Intermittent

EC Buying Dual Spray USB Module

Best Dual Spray Design

- DC 5V

- 300mA

- 2-3W

- 108-110KHz

- 33.9×22.6x17mm

Six Spray TYPE-C Humidifier Module

Best Multi-Spray Module

- DC 5V

- 108KHZ ± 2KHZ

- 300MA

- 2.5-3W

- 50 * 25 * 1.2mm

Green Atomization Film Driver Board

Best Performance Driver Board

- High

- 1-100%

- Whisper-quiet

- 40kHz

- Plug-and-play

1.70MHz 25mm Ultrasonic Ceramic Atomizer

Best High-Frequency Option

- 1.70MHz

- 25mm

- Ultrasonic

- Ceramic

- Humidifier

Ultrasonic Humidifier Component Review

Choosing the Right Ultrasonic Humidifier Component

Understanding Component Types

Ultrasonic humidifier components aren’t one-size-fits-all. They range from complete modules ready for USB connection to individual replacement discs. The core of most systems is the ceramic disc, which vibrates at a high frequency to create mist. Other key components include the driver board (circuit board) that powers the disc, and modules that combine the disc and driver for easy integration. Knowing what you need – a full module, just a disc, or a driver board – is the first step.

Key Features to Consider

Frequency

The frequency of the ceramic disc (measured in MHz or kHz) is a crucial factor. Higher frequencies (like 1.70MHz) generally produce a finer mist, which is ideal for applications where visible droplets are undesirable, like sensitive electronics or delicate plants. Lower frequencies (around 108kHz) are more common and generally offer a good balance between mist output and efficiency. Mismatched frequencies between the disc and driver board will drastically reduce performance – ensure compatibility!

Disc Size & Material

Disc size (typically 16mm or 25mm) impacts the amount of mist produced. Larger discs generally create more mist, but require more power. The material of the disc is also important. Titanium-plated ceramic discs offer improved durability, corrosion resistance, and a longer lifespan compared to standard ceramic. Consider the environment where the component will be used; humid or corrosive environments benefit from titanium plating.

Spray Modes & Output Control

Some modules offer multiple spray modes (continuous, intermittent, dynamic). Intermittent modes conserve water and energy. More advanced driver boards include humidity and temperature sensors allowing for automated mist output adjustment. This is beneficial for maintaining a consistent humidity level without manual intervention. The amount of mist produced (spray volume) is directly tied to the power draw and the disc size.

Additional Features

- LED Lighting: Some modules include built-in LEDs for aesthetic appeal, offering dynamic color-changing or static color options.

- Automatic Shut-Off: A safety feature that automatically turns off the component when the water level is low, preventing damage.

- Connection Type: USB modules are convenient for portable projects, while driver boards may require external power supplies.

- Material Quality: Look for components made with durable materials like FR-4 PCB boards for the driver, and high quality ceramic for the discs.

Ultrasonic Humidifier Component Comparison

| Product | Disc Diameter (mm) | Voltage (V) | Current (mA) | Spray Modes | LED Lighting | Best For |

|---|---|---|---|---|---|---|

| 6Pcs USB Humidifier Module with LED | N/A | 5 | N/A | Continuous, Intermittent | 7-color, Dynamic/Steady | Best Overall |

| ITROLLE 4PCS 16mm Ultrasonic Discs with Wires | 16 | N/A | N/A | N/A | N/A | Best Value Replacement |

| MTDELE 5Pcs USB Humidifier Module | N/A | 5 | 300 | N/A | N/A | Best for DIY Projects |

| Green Atomization Film Driver Board | N/A | N/A | N/A | Automatic (1-100%) | N/A | Best Performance Driver Board |

| SQXBK 8PCS 16mm Ceramic Discs | 16 | N/A | N/A | N/A | N/A | Best Budget Pack |

| 1.70MHz 25mm Ultrasonic Ceramic Atomizer | 25 | N/A | N/A | N/A | N/A | Best High-Frequency Option |

| Six Spray TYPE-C Humidifier Module | N/A | 5 | 300 | Continuous, Dynamic, Indirect | White Light | Best Multi-Spray Module |

| EC Buying Dual Spray USB Module | N/A | 5 | 300 | N/A | N/A | Best Dual Spray Design |

Testing & Data Analysis: Ultrasonic Humidifier Components

Our evaluation of ultronic humidifier components relies on a data-driven approach, combining manufacturer specifications with independent testing and comparative analysis. We prioritize components offering clear technical documentation, including frequency response curves and mist output data at varying voltages.

Where possible, we conduct physical testing, measuring mist output volume (mL/hour) using calibrated collection methods and droplet size analysis via microscopy. We assess the longevity of ceramic discs by running extended burn-in tests (72+ hours) and monitoring performance degradation.

However, given the diverse range of available modules and the challenges of standardized testing, a significant portion of our analysis centers on reviewing published datasheets and user reports. We compare component specifications – specifically frequency (1.70MHz vs 108kHz), disc size (16mm, 25mm), and materials (titanium-plated vs standard ceramic) – against performance claims. We analyze user feedback regarding durability, noise levels, and compatibility with various driver boards. The presence of features like automatic shut-off and humidity sensors are also assessed based on their potential impact on usability and safety. Our findings are correlated with the Buying Guide recommendations to ensure alignment between component features and practical applications.

FAQs

What frequency ultrasonic humidifier component should I choose?

The best frequency for your ultrasonic humidifier component depends on your application. Higher frequencies (like 1.70MHz) produce a finer mist suitable for sensitive electronics, while lower frequencies (around 108kHz) offer a good balance of mist output and efficiency for general use.

What is the benefit of a titanium-plated ceramic disc?

Titanium-plated ceramic discs offer improved durability and corrosion resistance compared to standard ceramic. This makes them ideal for use in humid or corrosive environments, extending the lifespan of your ultrasonic humidifier component.

What disc size should I choose for my project?

Disc size (16mm or 25mm) impacts mist output. Larger (25mm) discs produce more mist but require more power. Choose a disc size based on your desired mist volume and available power supply.

What features should I look for in a driver board?

Consider driver boards with features like automatic shut-off for safety and humidity sensors for automated mist output adjustment, providing consistent humidity levels and reducing manual intervention in your ultrasonic humidifier component system.

The Bottom Line

Choosing the right ultrasonic humidifier component requires careful consideration of your specific needs and application. From frequency and disc size to spray modes and material quality, understanding these factors will ensure optimal performance and longevity of your project.

Ultimately, a well-informed decision will lead to a more efficient and reliable humidification solution. Whether you’re building a DIY project or replacing a worn-out part, prioritizing compatibility and quality will deliver the best results.