Your humidifier hums to life, the water reservoir empties, but the room stays dry as a desert. That silent fan means your device is just a fancy water dish—no mist, no moisture relief. When the fan stops spinning, healthy humidity levels vanish fast, leaving you with static shocks, dry sinuses, and cracked wood furniture. This guide cuts through the confusion with precise diagnostics and fixes for every humidifier type. You’ll pinpoint whether it’s a clogged blade, fried motor, or wiring blunder—and know exactly when to repair versus replace. Let’s get your air moving again in under 30 minutes.

Spot These Critical Fan Failure Signs Immediately

Room Humidity Plummets Overnight

A working humidifier boosts indoor humidity by 2–5% hourly. When your fan dies, expect a 10% humidity crash within 48 hours even as water drains from the tank. Grab a $10 hygrometer—anything below 30% RH confirms the fan isn’t circulating air through the evaporator pad. Don’t blame the weather; this rapid drop means your unit is failing silently while “running.”

Power On But Zero Airflow

Your control panel lights up, settings change, yet no breeze exits the vents. Hold your palm 2 inches from the discharge slot—total stillness proves fan failure, not weak output. If you feel faint air but no mist, the fan is struggling with mineral buildup. Complete silence during operation? The motor isn’t receiving power or has seized.

Water Flows Without Mist Production

Listen for the solenoid’s click as water hits the evaporator panel. If you hear water but see no mist or feel cool air, the fan isn’t pulling room air through the system. This wastes water and invites mold growth inside the unit. Immediate action stops costly secondary damage.

Power Down and Verify Your Electrical Foundation

Eliminate Deadly Outlet Mistakes First

Unplug the unit before touching internals—furnace-mounted models stay live through the HUM terminal during heating cycles. Test the outlet with a phone charger: 30% of “fan failures” stem from tripped GFCIs in basements or shared circuits. Reset the outlet, then retest. If dead, check your breaker panel for labeled “humidifier” or “furnace” switches.

Inspect Cords for Hidden Damage

Run fingers along the entire power cord length. Exposed wires or melted insulation increase fire risk 400% in humid environments. Pay special attention to bends near plugs—these fracture first. Never tape damaged cords; replace immediately with UL-listed 16-gauge cords matching your unit’s amperage.

Run the 2-Minute Manual Spin Test

Diagnose Blade Obstruction Causes

With power disconnected, gently rotate fan blades by hand:

– Sticky resistance? Mineral crust or dust bunnies jam the shroud.

– Metallic scraping? A bent blade hits the housing—common after vacuuming nearby.

– Complete seizure? Mineral lock has fused bearings (typical in hard water areas).

Pro Tip: Use a soft toothbrush dipped in white vinegar to dissolve scale on blades. Never spray liquid directly—dab the brush only.

Confirm Electrical Failure If Blade Spins Freely

If blades rotate smoothly with zero drag, the motor or control circuit has failed. Skip cleaning—proceed straight to voltage testing. Mechanical issues cause 65% of fan stops; free-spinning blades mean you’re facing electrical gremlins.

Voltage Test Like a Pro (No Engineering Degree Needed)

Portable Units: The 120VAC Plug Test

Set multimeter to AC voltage. With humidistat calling for moisture:

1. Measure outlet voltage—should read 110–125V. Below 100V? Circuit overload.

2. Touch probes to motor terminals while unit runs—identical voltage confirms power delivery.

3. Zero volts at motor? Your humidistat or control board isn’t signaling.

Critical Insight: If voltage disappears when humidistat reaches target humidity, the sensor is faulty—not the fan.

HVAC Systems: Decode the 24VAC Puzzle

Furnace units use low-voltage control wires:

– Check HUM terminal voltage only when burners fire—should hit 24VAC.

– Test brown control wires at humidifier—voltage here triggers the fan.

– Bypass test: Plug unit’s 120V cord into a wall outlet via extension cord. Fan spins? Your furnace wiring is faulty.

Warning: Never connect 24V wires to 120V lines—this fries control boards instantly.

Fix Model-Specific Fan Failures Fast

Essick Aircare 831000: Float Switch Secrets

This popular console model halts the fan if water level drops. Remove the back panel to access the float rod—mineral deposits often jam its movement. Soak the rod in vinegar for 10 minutes. If the fan still won’t run after cleaning, replace the $45 motor—but new units cost $90 at Walmart. At this price point, replacement often beats repair.

Aprilaire 700 Gray Case Wiring Fix

Newer gray-case Aprilaires fail when miswired:

– 120V plug must connect to always-live outlet (not HUM terminal).

– Brown control wires need 24VAC only during heating cycles.

– Neutral wire MUST land on neutral bus—grounding causes instant failure.

Quick Test: Run an extension cord from wall outlet to humidifier. Fan spins? Rewire per Aprilaire’s diagram—90% of “dead fan” calls stem from this error.

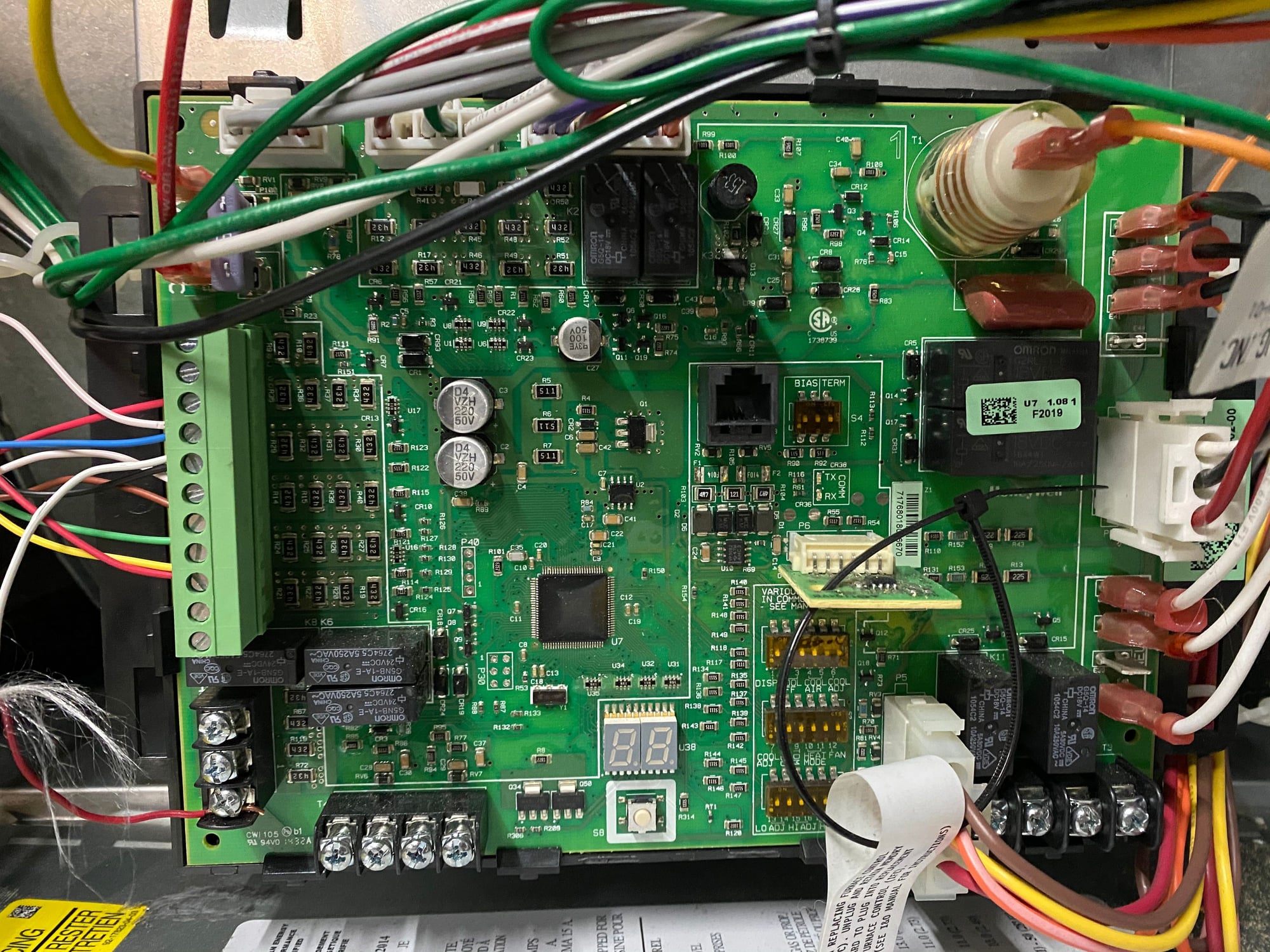

When Control Boards Fail

Burnt plastic smell or black scorch marks on the circuit board mean replacement time. DIY kits run $120–200 but require soldering skills. Call an HVAC pro—furnace board compatibility is complex, and one wrong wire disables your entire heating system.

Prevent Repeat Failures With Smart Maintenance

Weekly Blade Care Routine

- Vacuum shroud vents with crevice tool to prevent dust buildup.

- Wipe blades with vinegar-dampened cloth during water refills.

- Never use compressed air—it forces moisture into motor windings.

Pro Tip: Place a microfiber cloth over vents when unit is off to block dust during storage.

Seasonal Deep Clean Protocol

- Remove fan assembly and rinse blades under warm tap water (no soap!).

- Dry for 24+ hours on a towel—moisture causes motor shorts.

- Replace evaporator pads monthly in hard water areas—clogged pads strain fans.

Critical: Always use distilled water in portable units. Tap water leaves mineral scale that seizes bearings in 6–12 months.

Know When to Call a Technician

Complex HVAC Integration Red Flags

Seek professional help if:

– HUM terminal shows 0V during burner operation (furnace board issue).

– Multiple control wires confuse your wiring diagram (e.g., R, C, Y terminals).

– Burn marks appear on furnace control board near humidifier wires.

Cost Reality Check: Service calls start at $150. If the fan motor costs $60 and labor is $100/hour, repair only makes sense if your unit is under warranty. For portables under $100, replacement is smarter.

Maintain Peak Performance Year-Round

Daily Habits That Extend Fan Life

- Empty reservoir nightly to prevent biofilm growth.

- Refill with distilled water—hard water kills fans 3x faster.

- Wipe mist nozzle with rubbing alcohol weekly to avoid clogs.

Whole-House System Upgrades

- Install an inline water filter ($25) to cut mineral intake.

- Set humidistat 5% below furnace’s max (usually 35%) to prevent overworking.

- Test sensor accuracy yearly with a separate hygrometer.

Quick Diagnostic Flowchart for Silent Fans

- Outlet test → Lamp works? = Power confirmed

- Spin test → Stuck blade? = Clean debris

- Voltage check → 120V at motor? = Replace motor

- Extension cord test → Fan runs? = Rewire furnace connection

- Humidistat check → Clicks when set high? = Sensor working

- Cost analysis → Motor >50% new unit price? = Replace entire humidifier

A silent humidifier fan typically fails from three root causes: dust obstruction, electrical faults, or wiring errors. Start with the 2-minute spin test—70% of issues resolve with simple cleaning. If voltage tests confirm power but no spin, replace the motor unless repair costs exceed half the price of a new unit. For furnace models, always verify the 120V plug is on an always-live circuit, not the HUM terminal. Commit to weekly blade wipes and distilled water refills, and your fan will deliver steady humidity for years. When in doubt, that extension cord test separates wiring errors from true motor death—saving you unnecessary service calls.